- Energy Solutions

- Air Solutions

- Water Solutions

친환경솔루션

친환경솔루션

글로벌 환경규제 동향과

수소사업, 대기환경, 수질환경

솔루션을 확인할 수 있습니다.

사업소개

대기·수질 환경을 보호하는 파나시아의 친환경 에너지 설비 사업을 소개합니다.

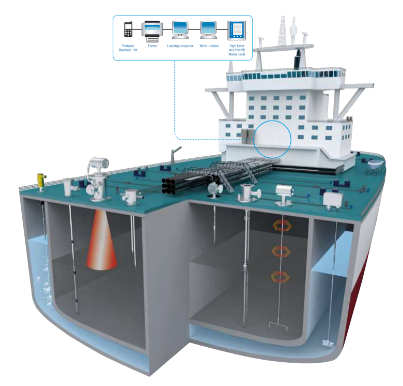

선박수위제어계측장비

파나시아의 선박용 제어계측 시스템은 선박 내 원유, 연료, 선박평형수 탱크의 수위, 양, 온도, 흘수 등을 계측하여 제어할 수 있으며, 모니터링 및 알람기능까지 갖추어 선박이 안전하고 안정적으로

운항할 수 있는 토대를 제공 합니다.

-

1.Cargo monitoring system

Radar beam type

Magnetic float type

-

2.High & overfill alarm system

Magnetic float type

-

3.Tank level & draft gauging system

Air purge type / Electric pneumatic type

Electric pressure type

-

4. Vapour emission control system

-

5. Fixed gas detection system

-

6. Water ingress alarm system

-

7. Pressure / Temperature monitoring system

-

8. Bilge high level alarm system

-

9. Local level gauge / switch

-

10.Pressure switch / temperature sensor / pressure transmitter

LEVEL-3000™의 작동원리는 다이아프레임과 4가닥의 통기되는 특수전선에 연결되는 증폭기로 구성된 두 가닥 전선의 압력식 수위계측 전송기입니다.

Transducer는 특수오일로 채워진 내부에 휘스톤 브릿지 타입의 스트레인 게이지가 내장되어

있으며 이것은 다이아프레임 표면의 압력변화를 감지하게 되고 피 측정체인 액체의 압력이 다이아프레임 표면에 가해지면 스트레인 게이지가 응력을 받아 저항이 변하게 됩니다.

이 저항의 변화는 아날로그 신호처리 회로를 통해 4~20㎃의 전류값 또는 RS485 통신신호로 만들어지며 LEVEL-3000™은 다른 4~20㎃의 전류값 출력 전송기와 호환됩니다.

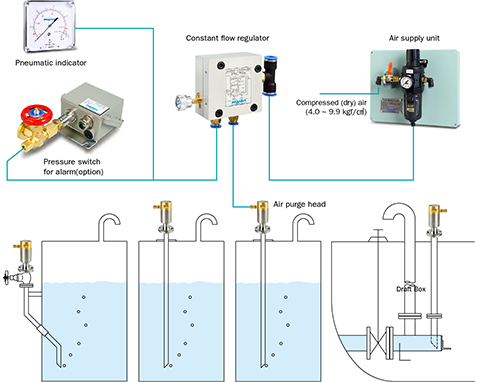

기포식 수위계측 시스템은 원리, 구조, 설치가 간단하고 비교적 경제적인 가격으로 다양한 종류의 수위 측정에 적합하다. 선박의 연료유탱크, 각종 기름탱크, 밸러스트탱크 등의 수위와 양(volume)의 측정과 선박의 잠김상태 즉 전ㆍ후, 좌ㆍ우 흘수(Draft) 측정에 널리 사용되고 있습니다.

기포식 수위계측 장치의 작동원리는 여과를 거친 공기를 공습관을 통해 연속적으로 탱크내부 측정관에 주입하여 피측정 액체의 수두압에 상응하는 배압을 이용하여 수위를 측정하는 원리입니다.

즉 탱크 내부 액체의 밑바닥까지 파이프를 삽입하고 일정량의 공기를 불어넣으면 수위에 상응하는 압력보다 높게 형성된 공기는 파이프 끝단에서 기포로 방출 됩니다. 이 때 파이프 내부 공기압은 액체의 수두압에 상당하는 압력이 형성되고 이 수두압을 액체의 비중으로 나누면 액체의 수위를 측정할 수 있게 됩니다.

따라서 탱크내의 액체의 수위와 수위에 상응하는 용량(volume)을 계기 눈금판(indicator scale plate)에 새겨서 탱크내의 액체 높이(level)와 양(volume)을 계측할 수 있습니다.