- This is PANASIA

- Business locations

- ESG Management

- History

- Smart PANASIA

About

About

Check PANASIA introduction,

ESG management, and History

information

- Energy Solutions

- Air Solutions

- Water Solutions

Eco-friendly Solution

Eco-friendly Solution

About Global environmental

regulation, Hydrogen business,

Air quality, and Water quality

environment solutions

- Product Service

- Service Network

- Customer Service

Customer Support

Customer Support

Check the Panasia’s

after service

- About

- Eco-friendly Solution

- Customer Support

- Media

Water Solutions

- Eco-friendly Solution

- Water Solutions

- Water treatment system

Water Treatment System

Product Description

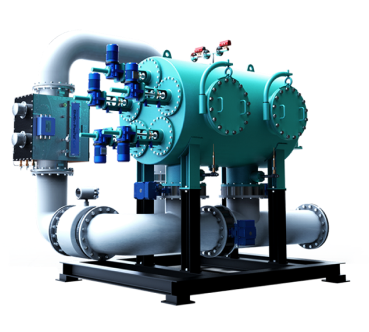

PANASIA’s water treatment system “GloEn-Patrol™” is a water quality solution. It is recognized as the most eco-friendly and safest system, as it uses a 100% physical filter treatment process and UV disinfection technology based on UV lamps.

GloEn-Patrol is widely used for both onshore and offshore applications where water treatment is required. It can be used for water purification in onshore plants, and for water treatment in water mains and sewers.

When used for offshore applications, it helps protect marine ecosystems by sterilizing microorganisms in ballast water on ships, which pose one of the most serious threats to the marine environment. Ships repeatedly take in and discharge ballast water to stay balanced. But when they do, microorganisms are also taken on board and discharged, which has negative effects on the ecosystem. This problem associated with ballast water has become a global issue, compelling the IMO to announce in 2017 that it is mandatory for all ships to install ballast water treatment systems.

To meet this requirement, PANASIA continued to pursue R&D on improving water quality on land and in the sea, which eventually led to the development of GloEn-Patrol

Certificate

| Class | DNV Type Approval |

LR Type Approval |

KR Type Approval |

ABS Type Approval |

RINA Type Approval |

RMRS Type Approval |

BV Type Approval |

CR Type Approval |

CRS Type Approval |

| Flag | USCG Type Approval |

Korea Type Approval |

Norway Type Approval |

Cyprus Type Approval |

Germany Type Approval |

Saint Kitts And Nevis Type Approval |

Croatia Type Approval |

Palau Type Approval |

Cook Islands Type Approval |

| Taiwan Type Approval |

Turkey Type Approval |

Russia Type Approval |

Greece Type Approval |

Italy Type Approval |

France Type Approval |

||||

| Explosion-proof | Ex-Proof DNV ATEX Type Approval |

IECEx Type Approval |

History

-

2020

-

2020.03

Acquired USCG type approval

(GloEn-Patrol 2.0)

-

-

2019

-

2019.12

Delivery of 1,000 PCS of system

-

2019.11

Selected as a World-Class product by the Ministry of Trade - Industry

-

2019.08

Acquired New G8 type approval (DNV)

-

-

2018

-

2018.12

Acquired USCG type approval

-

-

2016

-

2016.03

Received IR52 11th week’s Jang Young-shil Award

(Ultraviolet sterilizer for large capacity)

-

-

2015

-

2015.01

Acquired IECEx certificate of conformity proof

Acquired G8 type approval for large capacity

– UV unit : PU1000, PU1250, PU1500

-

-

2012

-

2012.12

Designated as a World Class Product of Korea

-

-

2011

-

2011.08

Received IR52 32th week’s Jang Young-shil Award

(GloEn-Patrol ™-Ballast Waster Treatment System)

-

-

2010

-

2010.08

Delivered GloEn-PatrolTM Unit #1

-

2010.06

Acquired the World’s first ATEX

(EC-type examination certificate) (DNV)

- Sales various products installed in hazardous areas -

2010.03

Acquired final approval for active substances (MEPC 60th)

-

-

2009

-

2009.12

Acquired government’s

(The Ministry of Land Transport and Maritime Affairs)

type approval for BWTS, GloEn-PatrolTM -

2009.11

Implementation of conformity test

-

2009.06

Conducted a shipboard test

-

-

2008

-

2008.07

Implementation of land base test

-

2008.02

Completed Production of the test facility barge(trial vessel)

and conducted a product test

-

-

2004

-

2004.10

- BStarted BWTS R&D (Research and Development)

- Start lab-scaled model fabrication and test

- Proceeded with study of active substance approval.

-

Regulation trend

Up to 8 September 2024, for existing ships are required to install a ballast Water Treatment System

The agreement came into effect in 2017 as IMO's Ballast Water Management Convention was finally ratified by Finland.

(data: flickr)

-

Goal of implementing the IMO (International Maritime Organization) Ballast Water Management Convention

Goal of implementing the IMO (International Maritime Organization) Ballast Water Management Convention

-

Requirements for Entry into Force of the Ballast Water Management Convention

Requirements for Entry into Force of the Ballast Water Management Convention

-

The Ballast Water Management Convention officially comes into force

The Ballast Water Management Convention officially comes into force

Component Line-up

-

Original Filter Unit

Original Filter UnitType : Single screen type

Capacity : 50 ~ 750m³/hr

Max. Operating Pressure : 10 bar

Grade of filtration : 50μm

Filter Element Material : SUS 316L / Hastelloy

Backflushing control : Differential Pressure-dependent

-

MEGA Filter Unit

MEGA Filter UnitType : Multi cage screen type

Capacity : 900 ~ 3,000m³/hr

Max. Operating Pressure : 10 bar

Grade of filtration : 50μm

Filter Element Material : SUS 316L / Hastelloy

Backflushing control : Differential Pressure-dependent

| MW | Model | Treatment Capacity |

|---|---|---|

| Original Filter Unit | PF 50 | 50m³/h |

| PF 250 | 250m³/h | |

| PF 500 | 500m³/h | |

| PF 750 | 750m³/h | |

| MEGA Filter Unit | PF 900 | 900m³/h |

| PF 1200 | 1,200m³/h | |

| PF 1500 | 1,500m³/h | |

| PF 2000 | 2,000m³/h | |

| PF 2500 | 2,500m³/h | |

| PF 3000 | 3,000m³/h |

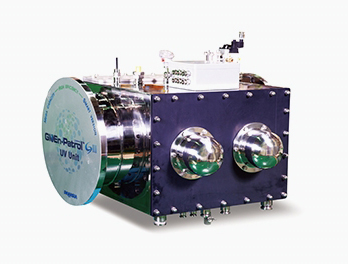

Component Line-up

-

Original UV Unit

Original UV UnitCapacity : 50 ~ 750m³/hr

Max. Operating Pressure : 10 bar

Automatic cleaning wiper

Explosion Proof Type (option)

-

MEGA UV Unit

MEGA UV UnitCapacity : 1,000 ~ 1,500m³/hr

Max. Operating Pressure : 10 bar

Automatic cleaning wiper

Explosion Proof Type (option)

| Model | Treatment Capacity | |

|---|---|---|

| Original UV Unit | PU 50 | 50m³/h |

| PU 250 | 150m³/h | |

| 250m³/h | ||

| 350m³/h | ||

| PU 500 | 500m³/h | |

| 700m³/h | ||

| MEGA UV Unit | PU 1000 | 1,000m³/h |

| PU 1250 | 1,250m³/h | |

| PU 1500 | 1,500m³/h |

Training Center

| No. | Country | Location | Company | Contact | |

|---|---|---|---|---|---|

| T/C-01 | U.S.A | TEMPA | C&C PANASIA Inc. | Mr.Ernie Chang | echang@ccpanox.com |

| T/C-02 | GREECE | ATHENS | BPCO LTD | Mr.Arsenios Papatheodorou |

info@bpco-group.com |

| T/C-03 | KOREA | BUSAN | PANASIA H/Q | Mr. Justin Bae | marketing@worldpanasia.com |

| T/C-04 | ESTONIA | TALLINN | BLRT Gropp | Mr.Viktor Vassiljev | vv@blrt.ee |